Ladybird is an automatic optical inspection (AOI) system designed specifically for through-hole components - THT AOI. Visit our sister site - www.thtaoi.com

Fast

SUNZ's innovative FuzzicalZ technology enables Ladybird to verify a typical board in less than 12 seconds. Its faster, simpler, and more reliable than systems with a moving camera. Ladybird doesn't use image comparison, so it can work quickly, even in shifting light conditions.

Flexible

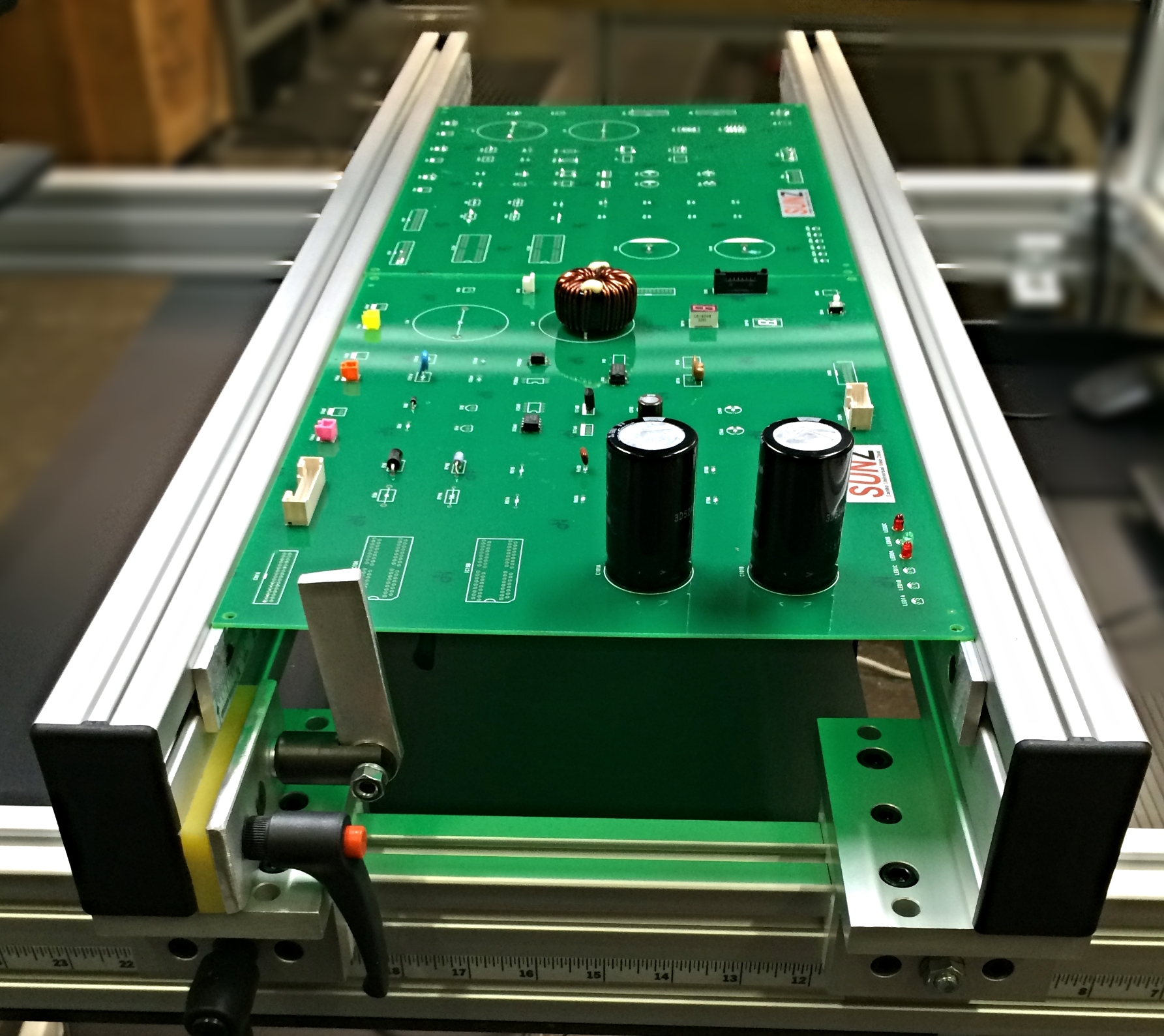

Ladybird's novel design allows it to verify components up to 80mm tall. You can perform both top side and solder-side inspections with one system. Programming and debug is done offline without disrupting testing. Inspection images and statistical data can be used for process improvements.

Affordable

Ladybird is made specifically for through-hole AOI by SUNZ in Japan. It is much more affordable than typical surface-mount AOI systems. It can be used for inspecting top side, bottom side, conformal coating and final assemblies. Ladybird is reliable, easy to train and easy-to-operate.

Use the Ladybird inline or as a batch process for through hole components and reduce manufacturing defects, increase yields, reduce labor costs and improve margins in one of the most costly areas of your process.

Customer Comments

"The Ladybird is very fast and is having a very positive impact. We are definitely improving our quality to our customers who do not have us test their boards."

"The Ladybird has figured out how to inspect a process that rules-based AOI systems can not; way to break the rules!"

Ladybird THT AOI Demo

Typical Inspections

Featured Images

More images…

Videos

Ladybird AOI Demonstration Video

Ladybird AOI FuzzicalZ Introduction